Immerse yourself

in the future of

water pressurisation. An efficient and versatile “all in one” product.

This "all-in-one" product is capable of meeting all manner of expectations.

THE VALUE

OF SIMPLICITY

EsyBox Diver breaks out of the submersible pump norms to become the residential solution with perfect performance: absolutely efficient, technologically advanced but extremely simple to use. Reliability and comfort are close at hand.

ALL IN ONE, BUT

WITH INFINITE ADVANTAGES

EsyBox Diver is the first electronic submersible pump with integrated Variable Frequency Drive to have a user interface for remote control. The Dconnect Box 2 is standard so installation, monitoring and performance management are quick and easy with the DConnect App. Electronics and connectivity combine to offer an efficient, versatile and suitable product for the needs of each user: a thousand solutions in one for residential home pressurization.

Irrigation

reuse

from below ground

TECHNOLOGY + CONNECTIVITY: THE CROSSOVER OF SUBMERSIBLE PUMPS

More than 40 years of experience. An unstoppable drive for innovation. Constant communication with all markets. Listening to create solutions.

This is the ecosystem in which DAB's products are created and evolve.

INTEGRATED VESSEL

The expansion tank improves the airtightness of the system, prevents it from restarting unnecessarily, provides protection against hammering effects and extends the life of the pump. This integrated component allows for quicker installation. A system more streamline and compact. Greater reliability over time.

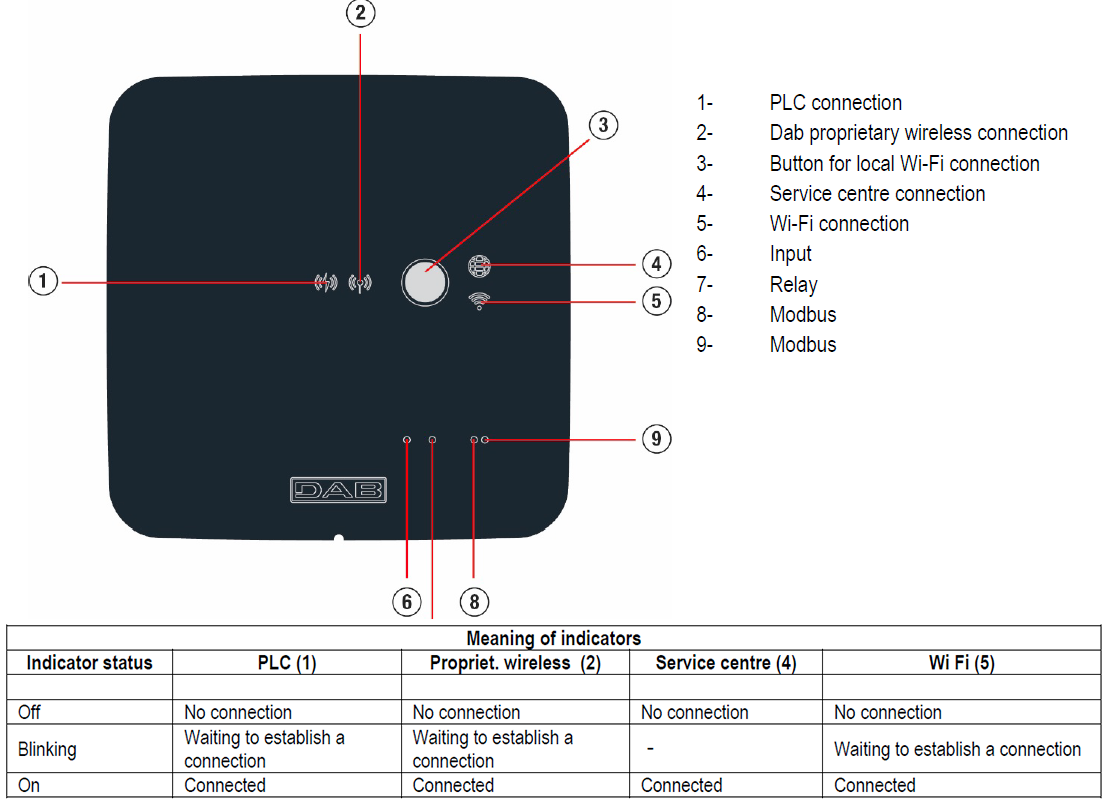

NFC AND PLC TECHNOLOGIES

Simple and constant control of the pump. Maximum ease and autonomy of installation of the accessories. NFC (Near Field Communication) permits the use of pumps with a float switch and water level measurement* without the need for any additional wiring. The accessories can be attached and do not require to open the pump body. All this guarantees speed and reliability. PLC* (Power Line Communication) permits the use of the DConnect Box 2 electronic control device not through any physical connection but via the power input line.

PLC Technology

Simple and constant control of the pump. Maximum ease and autonomy of installation of the accessories. NFC (Near Field Communication) permits the use of pumps with a float switch and water level measurement* without the need for any additional wiring. The accessories can be attached and do not require to open the pump body. All this guarantees speed and reliability. PLC* (Power Line Communication) permits the use of the DConnect Box 2 electronic control device not through any physical connection but via the power input line.

AIR VENT VALVE

Benefits during installation and all use. The bleeding valve permits immediate priming upon initial installation and guarantees correct operation of the pump at all times.

DOC68

The DOC68 permits installation of the EsyBox Diver as a surface pump, even outdoor thanks to the ip68 certification.

Simpler maintenance

Modular and functional construction. The modular components of the pump make it easier to perform maintenance. The parts can be removed, repaired and replaced separately, simplifying the resolution of any issues and reducing maintenance costs.

DConnect Box 2

Convenience at hand DConnect Box 2 can monitor up to 4 pumps and be connected to the Internet only via Wi-Fi. Once connected, you simply need to follow the straightforward guided procedure of the App to connect it to the DAB Cloud and manage your pump in complete ease. For further information on the conditions of service, consult the website: internetofpumps.com/en-au.

ALWAYS IN

CONTACT WITH YOUR

SYSTEMS

Thanks to DConnect service, it is possible to manage activities and consumption of the EsyBox Diver or customise its parameters and alarms, monitor its operation and prevent the risk of malfunctions and blockages.

Discover your savings

with EsyBox Diver

Compared to a pumping system without variable frequency drive

FAQ

The pump and the DCONNECT BOX 2, if present, must be connected to the same power mains, avoiding their being galvanically separated, as for example due to the presence of open isolation transformers or switches, even single-phase ones. In particular condominium or industrial contexts, where single-phase users can be connected to different phases of the three-phase distribution provided by the public operator, the DCONNECT BOX 2 and the pump might not be able to communicate. After having correctly connected the hydraulic and electrical part, it is sufficient to supply power and the system is ready to work. The pump can be controlled and set through the appropriate app, installed on a smartphone or tablet. The app can be downloaded from https://internetofpumps.com/ or from the major stores. To enable the app to interact with the pump, the DCONNECT BOX 2 must be correctly installed and powered. The LEDs on the DCONNECT BOX 2 monitor the connection status with the pump and the app.

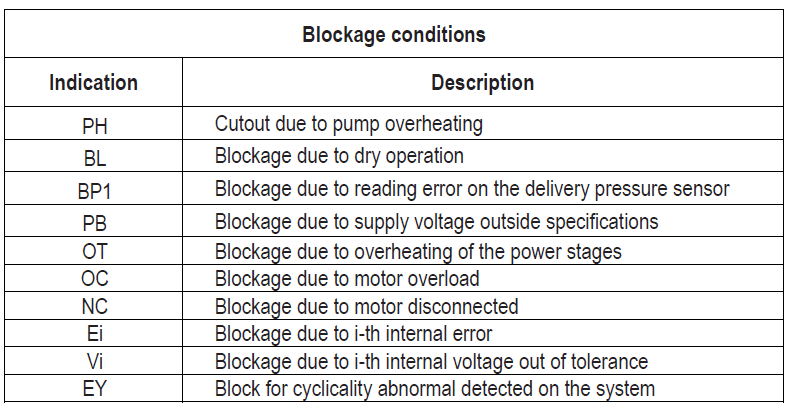

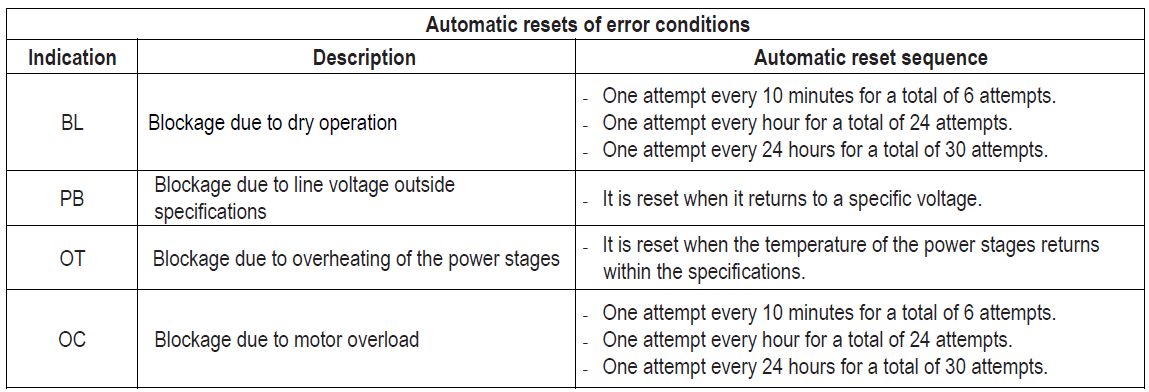

In the case of dry running the pump is stopped automatically after the time TB. After having restored the correct flow of water you can try to leave the protective block manually by sending the Error Reset command. If the alarm status remains, or if the user does not intervene by restoring the flow of water and resetting the pump, the automatic restart will try to restart the pump.

If there are leaks in the delivery section of the plant, the system starts and stops cyclically even if no water is intentionally being drawn: even just a slight leak (a few ml) can cause a fall in pressure which in turn starts the electropump. The electronic control of the system is able to detect the presence of the leak, based on its recurrence. The Anti-Cycling function can be excluded or activated in Basic or Smart mode. In Basic mode, once the condition of recurrence is detected the pump stops and remains waiting to be manually reset. This condition is communicated to the user with the "ANTICYCLING” message. After the leak has been removed, you can manually force restart by sending the Error Reset command. In Smart mode, once the leak condition is detected, the parameter RP is automatically increased to decrease the number of starts over time.

The change of state of water from liquid to solid involves an increase in volume. It is therefore essential to ensure that the system does not remain full of water with temperatures close to freezing point, to avoid breakages of the system. This is the reason why it is recommended to empty any electropump that is going to remain unused during the winter. However, this system has a protection that prevents ice formation inside by activating the electropump when the temperature falls to values close to freezing point. In this way the water inside is heated and freezing prevented. The Anti-Freeze protection works only if the system is regularly fed: with the plug disconnected or in the absence of current the protection cannot work. However, it is advised not to leave the system full during long peri- ods of inactivity: drain the system accurately through the drainage cap and put it away in a sheltered place.